The Burley Brampton 9108-C has a nominal heat output of 8kW yet when even more heat is required, the stove can produce an impressive maximum output of up to 11.7kW! Using Burley's latest innovations in wood burning, this powerful stove runs extremely efficiently with a rating of 85.6%.

The Burley Brampton 9108-C has a nominal heat output of 8kW yet when even more heat is required, the stove can produce an impressive maximum output of up to 11.7kW! Using Burley's latest innovations in wood burning, this powerful stove runs extremely efficiently with a rating of 85.6%.

Finished in matt black, this attractive steel bodied stove has a large ceramic glass viewing window providing a wonderful flame view that will become the main feature within any home. The timeless look of the stove is softened by wooden door handle and air control slider. A cover plate is included which can be used to cover the convention holes at the top of the appliance without having any affect on efficiency.

Part of the 'Fireball' range of stoves from Burley, the Brampton 9108-C exceeds the required levels of emissions for the upcoming EcoDesign directive. An environmentally friendly appliance that can also be used to burn wood in smoke controlled areas in the UK. The catalytic converter on this model aids complete combustion, turning carbon monoxide into carbon dioxide, releasing more energy in the process, therefore the stove with catalytic converter will generally have lower CO and higher efficiency than the stove without.

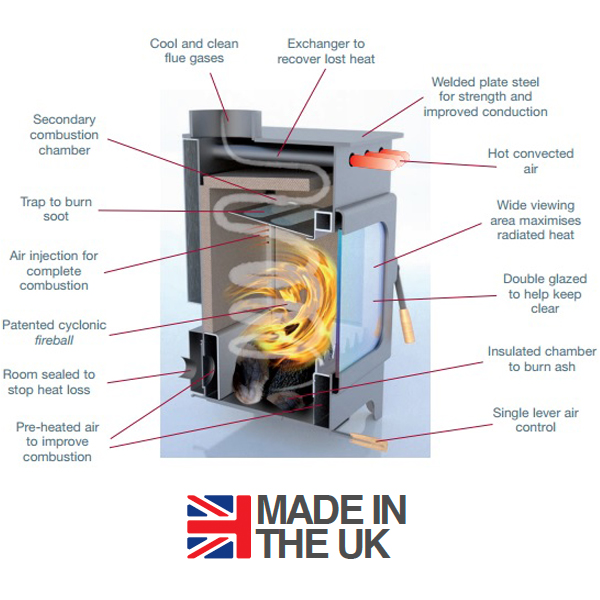

In each Fireball stove there is an advanced heat exchanger. This heat exchanger scrubs the energy from the hot gasses before they go up the chimney and puts more warmth into your home. The combination of efficient burning and heat recovery means that their wood burners will deliver more warmth and use less fuel than any comparable stove you may currently have.

As two of the main reasons for buying a stove are to be mesmerised by the flame picture and to keep you warm and cosy, Burley wanted the largest possible window. Due to its size and the intensity of heat generated, the screen has to withstand massive temperature fluctuations and thermal shock so it is actually ceramic and not conventional glass. Ceramic glass is very expensive, despite this your stove is double glazed which helps keep it clean and promotes secondary combustion.

Burley wood burning stoves are constructed in the UK using heavy gauge steel. The plate steel sections are 5mm and 8mm thick and are welded by robots. Hand-crafted is lovely when it comes to knitwear, but in a stove there is no comparison to welding by robots. Not only are the welds applied in exactly the right place and in exactly the right thickness, but the steel sections are actually melted and fused together to make a virtually indestructible construction.

Particulates

The particulates are the pieces of fine dust and soot which escape combustion and pass up the chimney, this is what air pollution in cities usually measures and focuses on. The intensity of Burley’s Fireball combustion ensures almost all particulates are burnt before they leave the combustion chamber, any which do escape the fierce heat then have to pass though Burley’s unique soot trap, this is a red hot stainless steel mesh on which particulates spontaneously combust on contact releasing even more energy. Any which survive the soot trap still have to make it through the catalytic converter where they are burnt through oxidation.

The combined effect of all these measures results in particulates as low as 0.1 grams per hour, just 1/30th of what is allowed for EcoDesign. Burning one single open fire produces more particulates than 300 Burley stoves! Buy a Burley Fireball and your neighbours will love you for it!

How perfect combustion of wood is achieved

Three part combustion

Burning wood efficiently requires a primary, secondary and tertiary combustion process.

Primary combustion

Primary combustion is the initial burning of the wood at relatively low temperatures. During primary burn, water is evaporated and large amounts of creosote gas are produced. This creosote holds 60% of the potential energy of the wood, but is often just deposited on the inside of the stove and the lining of the flue, which causes chimney fires.

Secondary combustion

If, however, the combustion chamber is designed correctly by having sufficient insulation to raise the core temperature to 400ºC, and the correct amount of air is introduced, this creosote spontaneously combusts. This creates a chain reaction which increases the temperature inside the stove from 400ºC to 600ºC with no extra use of fuel. This is the secondary burn.

Introducing the air

The Burley range of stoves has a unique and patented system of introducing air for combustion, This is called the Fireball. A tubular framework channels air from the intake at the rear, around the fuel bed where it is preheated. The framework extends up each corner of the combustion chamber where the hot air is injected horizontally along the inside of the stove. This creates a vortex which spins anticlockwise and ensures every area of the fire box receives exactly the correct amount of oxygen.

Tertiary combustion

Tertiary combustion occurs by fully burning the carbon, charcoal and ash which is left behind. These contain a huge amount of energy and provide a long rate of heat. Anyone who has barbecued will be aware of how much heat is present in semi-combusted wood. Blacksmiths melt steel on it. The vortex created by the Fireball technology also envelops the entire fuel bed, burning it so completely that there is no need for an ash pan. 100kg of wood can be reduced to 1 pint of ash (a ratio of 350:1) which is simply scooped out. No more carrying bucket loads of ash through the house every time you want a fire.

Quaternary combustion

To create even more heat for your room and less soot for your chimney, Burley’s stoves have a unique quaternary (fourth) combustion process. As the hot gases exit the combustion chamber they pass through a mesh filter. The mesh is heated to such a high temperature that when any particles of soot or creosote which have escaped the secondary combustion touch it, they are ignited on contact.

Results

Making a stove which will burn wood is very simple and cheap. Producing and designing a top quality stove which will burn wood efficiently and cleanly is very difficult and is expensive. During product approval, when the European test house was measuring the emissions from the Burley stove, the combustion was so clean they assumed that their gas analyser had broken and sent it away for recalibration.

Hydrocarbons

Hydrocarbons are the unburnt gasses escaping up your chimney, this is energy which is being lost. Burley’s patented Fireball method of injecting hot air ensures these gasses are burnt and their energy is used to heat your home.

Cover Plate

The convection holes are a feature of the stoves to increase efficiency. A cover plate is provided which may be fitted to cover the holes if preferred. the efficiency is not affected.

An extended base is available for all models. this is the perfect accompaniment for stand alone installations where height needs to be emphasised. this item is a separate component and fits to the standard height stove.

Room sealing

If you can room seal your stove it will have a great effect on how it warms your home. most stoves draw their air from the room, warm air which you have already paid to heat. An open chimney sucks all the air from your room once every single hour, 24 hours a day. This air is replaced by cold air creeping around windows and doors, chilling your entire house. A room sealed stove however draws the air directly from the outside, meaning all that lovely warmth stays in your room, radiating outwards throughout your home. It is Burley’s environmental policy to only make stoves which can be room sealed.

An optional Multi-Fuel Grate is available for this model which gives you the option of burning approved solid fuels.

An optional Multi-Fuel Grate is available for this model which gives you the option of burning approved solid fuels.

An optional Outside Air Kit can also be purchased as a Standard Room Seal Kit or Angled Room Seal Kit. The Standard Kit connects directly from the rear of the fire to the back wall. The Angled Kit exits at 900 from the rear of the fire. This can then be connected to standard ducts (available from builders’ merchants), to create a path to an outside wall. A maximum of five 900 angles may be used.

Included free with the Brampton 9108-C is Burley's 'Thank You' pack which typically contains:

Included free with the Brampton 9108-C is Burley's 'Thank You' pack which typically contains:

- Spanner to attach and adjust the tension of the air control lever

- Coaster to protect the top of your stove

- Moisture Meter to ensure your wood is dry

- Stove Paint in case you prefer black handles or ever need to touch up any paint work

- Heat Resistant Glove

- Scoop for removing ash

- Allen Key should you wish to adjust the door handle

- A Mug to enjoy a cup of tea whilst admiring the fantastic flame picture

The contents of the kits vary from model to model, so not all the items listed or shown above may be included with your stove.

Download Instructions

Download Brochure

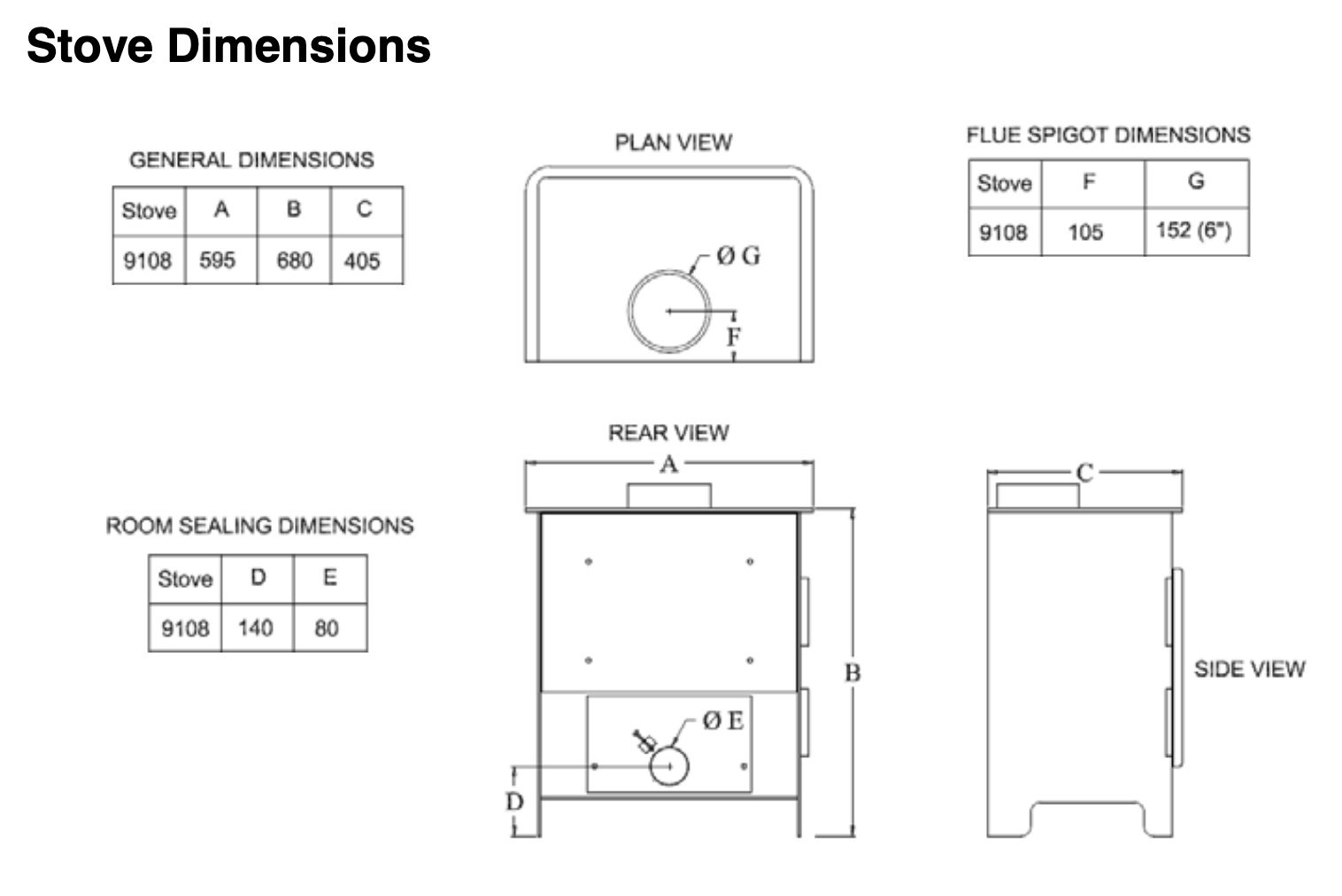

The dimensions (width, height, depth) of the Burley Brampton 9108-C Catalytic Converter Wood Burning Stove are listed here.

Optional Wood Store Base Plinth 183mm high

Please note: Due to rising freight charges, we are now being forced to charge extra for delivery to certain Scottish postcodes.

Due to the size and weight, all Burley Wood Burning Stoves will be delivered to you on a palletised delivery service. All pallet deliveries are kerbside/front door delivery only, so please arrange adequate means to take your order into your home. Under normal circumstances this may take 2 people.

Current delivery times for the Burley Brampton 9108-C is approximately 7-10 days however, this is dependant on stock levels at time of placing an order. Once an order is placed, we will contact you to advise if there is likely to be any delays on the estimated delivery time.

Returns information

We understand that from time to time some of our customers may change their mind or simply not be pleased with their chosen products once delivered and/or installed. Our returns policy should hopefully help with the process of returning your order in this instance. Please feel free to contact us should you have any further queries.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)